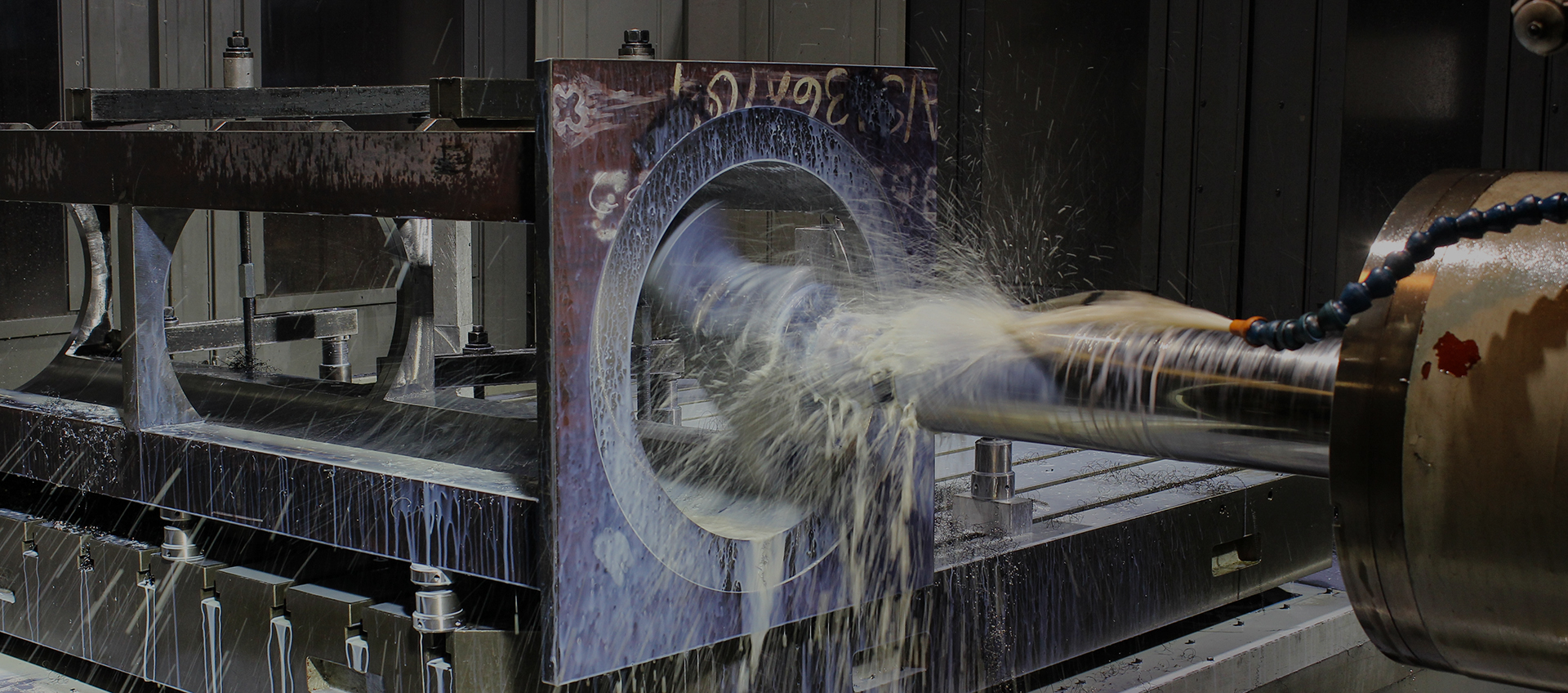

Pro-Cise is proud to announce that we recently purchased a new big-bore lathe to meet the turning/machining needs of the OEMs we serve.

This new equipment has expanded our capacity and speed to turn parts that include additional features such as counterbores, taps, milled flats, keyways, holes and more thanks to the live tooling feature.

Pro-Cise provides the ideal solution for parts that are 2” to 10” inches in diameter and 1” to 15” in length, such as:

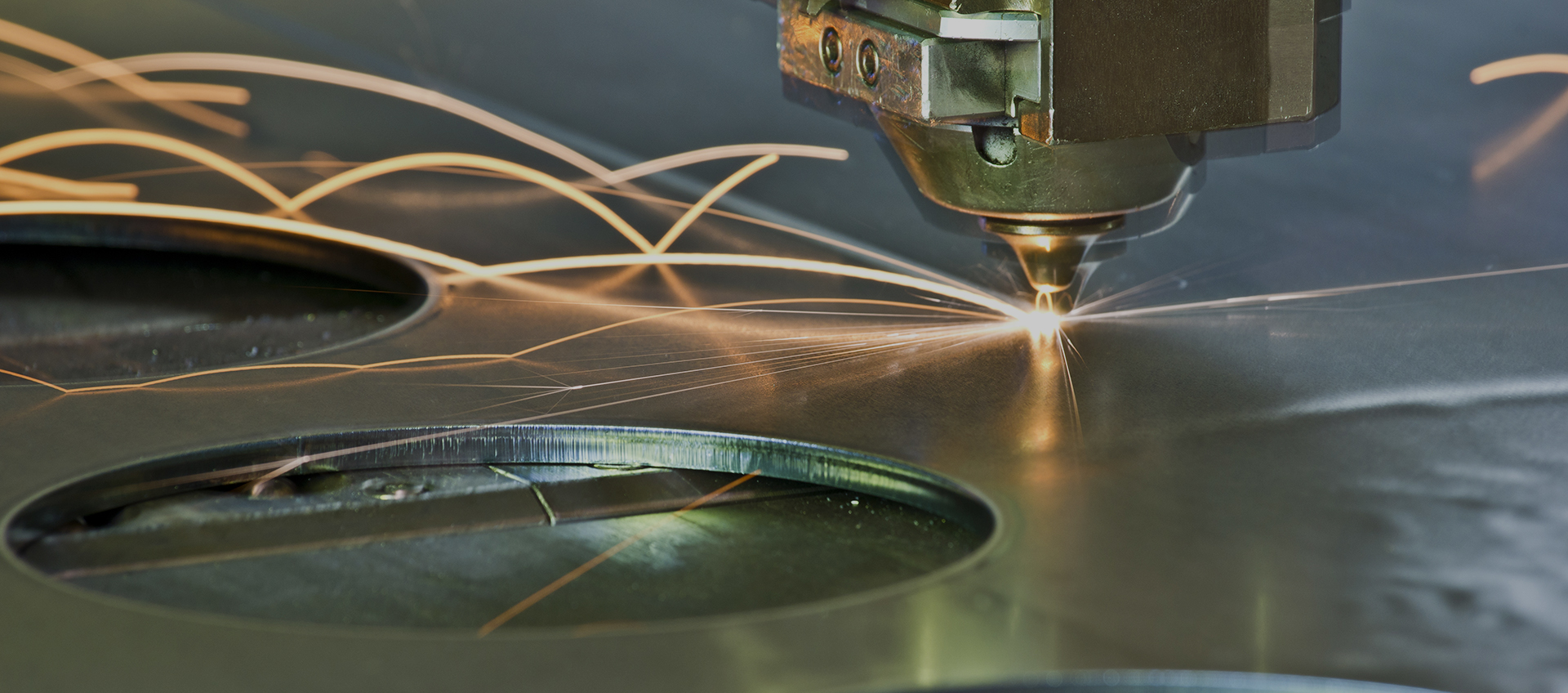

Pro-Cise specializes in providing turnkey fabrication, welding and manufacturing services to small and medium OEM equipment manufacturing companies. We hold multiple certifications for critical services and offer several in-house options. Our team is confident that we can handle any of your projects or requests.

Our 130,000-square-foot facility contains several loading bays and lifting hoists. We also have railway access that gives Pro-Cise various shipping method capabilities. Our facility lets us manufacture and transport large OEM components for many applications.

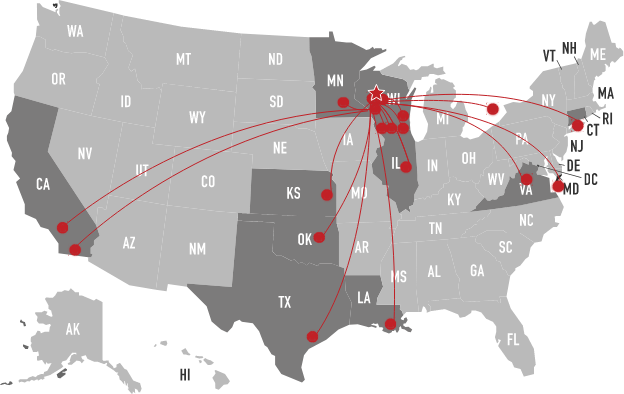

At Pro-Cise, we’re proud to serve customers across the U.S. Our facility is based in Eau Claire, Wisconsin, but our clients operate in several states, including California, Connecticut, Louisiana and Texas.

Explore All CapabilitiesAt Pro-Cise, our priority is the quality of our work. We’re dedicated to delivering well-made components to your company on time. We also strive to exceed your expectations and continuously enhance your experience as a customer. We’re constantly working to improve our products, services, workforce and quality management system.

Above everything else, Pro-Cise’s daily commitment is to you. Our team consists of highly skilled professionals who ensure that every OEM component we manufacture meets your specifications. To achieve this goal, we’ve implemented repeatable, industry-leading processes. We supplement those operations with cutting-edge inspection equipment. Our team also uses metrics from you and our suppliers to analyze our performance. This practice helps us find measurable ways to encourage continuous improvement.

Our quality management system works with our understanding of dimensional metrology and geometric dimensioning and tolerancing (GD&T). That combination gives Pro-Cise the ability to meet your expectations and build a solid relationship with your company.

We offer services based on your needs, including:

Our services are compatible with countless industries and equipment such as:

ISO 9001:2015 Certified Single Source Contract Manufacturing For OEM Components